Incorporating Streamlined Processes with Back Buckle Bonding Solutions for Enhanced Leather Manufacturing Efficiency

2025-07

Incorporating Streamlined Processes with Back Buckle Bonding Solutions for Enhanced Leather Manufacturing Efficiency

Table of Contents

- 1. Introduction to Back Buckle Bonding Solutions

- 2. The Importance of Streamlined Processes in Leather Manufacturing

- 3. Understanding Back Buckle Bonding Solutions

- 4. Benefits of Incorporating Back Buckle Bonding in Leather Processing

- 5. Best Practices for Implementing Back Buckle Bonding Solutions

- 6. Innovative Technologies in Back Buckle Bonding

- 7. Case Studies: Successful Implementation of Back Buckle Bonding Solutions

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Back Buckle Bonding Solutions

In the fast-paced world of leather manufacturing, efficiency is paramount. As industries strive for higher quality outputs at reduced costs, **back buckle bonding solutions** emerge as a pivotal advancement in this sector. This article explores how these solutions can be effectively integrated into **manufacturing processes**, leading to **improved productivity and quality**.

2. The Importance of Streamlined Processes in Leather Manufacturing

Streamlined processes are crucial in any manufacturing setting, especially in leather processing. The need to optimize production timelines while maintaining product quality can significantly impact a business's bottom line. Streamlined processes help in:

- **Reducing Waste**: Efficient procedures minimize raw material wastage.

- **Improving Quality Control**: Consistent methods enhance the quality of the final product.

- **Increasing Speed**: Faster operations lead to quicker turnaround times, fulfilling market demands swiftly.

- **Cost Efficiency**: Streamlining reduces operational costs, allowing businesses to reinvest savings into innovation and development.

By implementing back buckle bonding solutions, manufacturers can streamline their operations, reducing manual labor and minimizing errors, which ultimately enhances their competitiveness in the market.

3. Understanding Back Buckle Bonding Solutions

**Back buckle bonding solutions** refer to innovative techniques used in securely fastening leather pieces through adhesives or mechanical bonding methods. This process enhances durability and aesthetic appeal while ensuring that the product meets high standards of functionality.

Key components of back buckle bonding solutions include:

- **High-Quality Adhesives**: Specialized adhesives that provide strong bonds without compromising the leather's integrity.

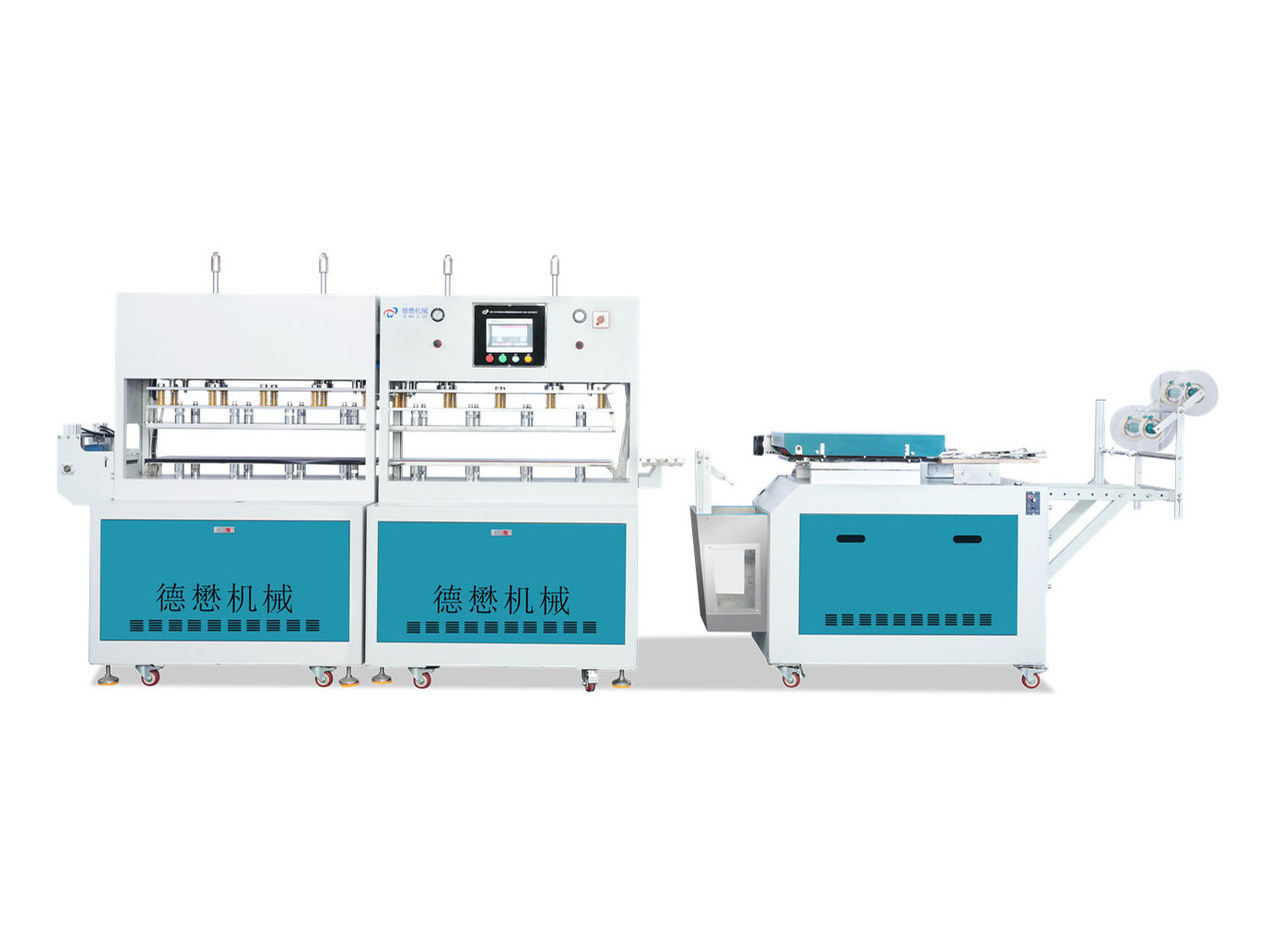

- **Automated Machinery**: Advanced equipment that facilitates precise application of adhesives or mechanical fasteners.

- **Quality Assurance Methods**: Testing protocols to ensure bonds meet industry standards for strength and flexibility.

By understanding these components, manufacturers can better integrate back buckle bonding into their existing processes.

4. Benefits of Incorporating Back Buckle Bonding in Leather Processing

The integration of back buckle bonding solutions into leather manufacturing processes offers numerous advantages:

4.1 Enhanced Durability

Bonds created through back buckle bonding are designed to withstand stress and wear, significantly extending the life of leather products. This durability is particularly important in high-use items such as belts, shoes, and bags.

4.2 Greater Flexibility

Back buckle bonding allows for more versatile designs. Manufacturers can create more intricate designs without compromising strength, enabling creativity and innovation in leather goods.

4.3 Cost-Effectiveness

By reducing the need for additional hardware and fasteners, back buckle bonding can lower production costs. Additionally, stronger bonds reduce the risk of returns due to product failure.

4.4 Improved Aesthetics

The bonding method provides a cleaner look without visible fasteners, appealing to consumers who favor sleek and modern designs.

5. Best Practices for Implementing Back Buckle Bonding Solutions

To successfully incorporate back buckle bonding solutions into leather manufacturing, consider the following best practices:

5.1 Invest in Training

Ensuring that staff are trained and knowledgeable about new bonding techniques is essential for successful implementation. Regular workshops and training sessions can keep teams updated on best practices.

5.2 Choose the Right Adhesive

Select adhesives specifically designed for leather applications. Conduct tests to find the right balance between bond strength and flexibility.

5.3 Monitor Quality Control

Implement strict quality control measures to regularly evaluate the strength of the bonds. This can involve both automated testing methods and manual inspections.

5.4 Upgrade Machinery

Investing in modern machinery that supports back buckle bonding will enhance speed and efficiency. Consider automation to minimize human error.

6. Innovative Technologies in Back Buckle Bonding

Technological advancements are continually enhancing back buckle bonding solutions. Key innovations include:

6.1 Automated Bonding Machines

Automated machines provide precise application of adhesives or mechanical bonds, significantly reducing the risk of human error and increasing production speed.

6.2 Smart Quality Control Systems

Utilizing sensors and AI for quality control allows manufacturers to monitor bonding effectiveness in real time, ensuring adherence to high standards.

6.3 Eco-Friendly Adhesives

The rise of sustainable manufacturing practices has led to the development of eco-friendly adhesives. These alternatives not only maintain bond integrity but also appeal to environmentally conscious consumers.

7. Case Studies: Successful Implementation of Back Buckle Bonding Solutions

Examining real-world examples can provide valuable insights into the effective implementation of back buckle bonding solutions:

7.1 Case Study: Premium Leather Goods Manufacturer

A leading producer of luxury leather handbags adopted back buckle bonding techniques, resulting in a 30% reduction in production time. By integrating automated bonding machines and training staff, they enhanced product quality and customer satisfaction.

7.2 Case Study: Footwear Industry Innovator

A footwear manufacturer implemented back buckle bonding solutions, leading to a dramatic decrease in product returns due to bonding failures. The choice of eco-friendly adhesives also improved the brand's marketability among sustainability-focused consumers.

8. Frequently Asked Questions (FAQs)

8.1 What is back buckle bonding?

Back buckle bonding is a method used to securely fasten leather pieces using adhesives or mechanical techniques, enhancing the durability and aesthetics of leather products.

8.2 How does back buckle bonding improve production efficiency?

By reducing the need for additional fasteners and manual labor, back buckle bonding streamlines the manufacturing process, allowing for quicker production cycles.

8.3 Are there specific adhesives for leather bonding?

Yes, there are specially formulated adhesives designed for leather that provide strong bonds while maintaining flexibility.

8.4 Can back buckle bonding solutions be automated?

Yes, many manufacturers are investing in automated bonding machines that enhance precision and speed while reducing manual errors.

8.5 What are the environmental impacts of using back buckle bonding solutions?

Many modern bonding solutions utilize eco-friendly adhesives, helping to reduce the overall environmental footprint of leather manufacturing.

9. Conclusion

Incorporating back buckle bonding solutions into leather manufacturing processes is a transformative step toward achieving enhanced efficiency, quality, and sustainability. By streamlining operations through innovative bonding techniques, manufacturers can not only improve their productivity but also create products that resonate with today’s discerning consumers. As the leather industry continues to evolve, embracing these advancements will be essential for maintaining competitiveness and fostering growth in a rapidly changing market.

Previous Page:

Related Information

Revolutionizing Leather Production: The Innovative Applications of Back Buckle Technology

Revolutionizing Leather Production: The Innovative Applications of Back Buckle Technology Table of Contents 1. Introduction to Back Buckle Technology in Leather Production 2. Historical Context of Leather Production 3. What is Back Buckle Technology? 4. Innovative Applications of Back Buckle Technology 4.1 Automation and Efficiency 4.2 Enhancing Qu

Why an Automatic Cold Cutting Machine is Essential for Modern Textile Manufacturing

Why an Automatic Cold Cutting Machine is Essential for Modern Textile Manufacturing Introduction to Automatic Cold Cutting Machines In the rapidly evolving world of textile manufacturing, **efficiency and precision** are paramount. The automatic cold cutting machine stands out as a game-changer in the industry, enhancing productivity while ensuring the highest quality of fabric cutting. This advan