Understanding the Double Head Reverse Packaging Hot Cutting Machine: A Key Player in the Garment Manufacturing Industry

2025-07

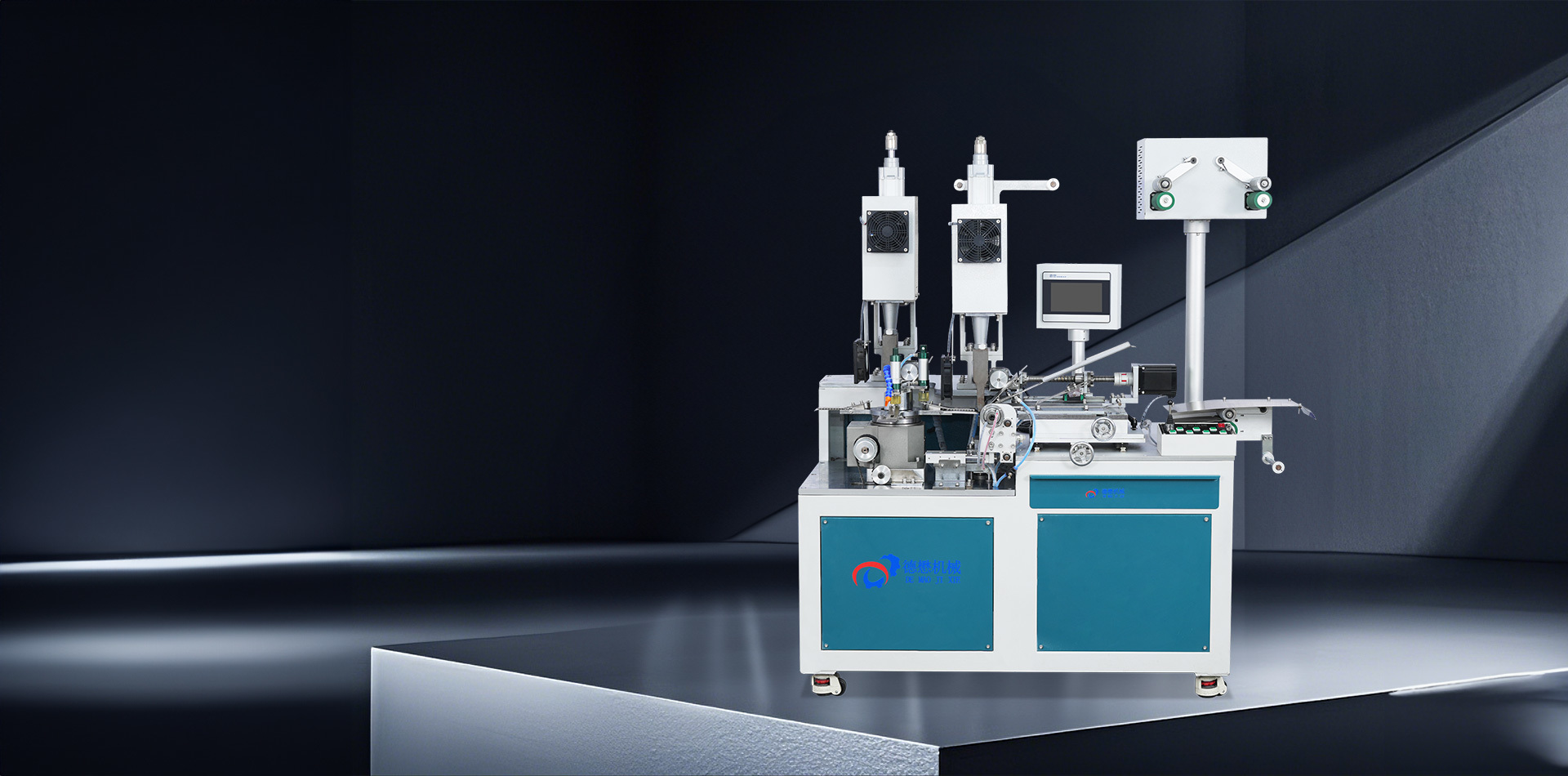

The double head feature of this machine allows for simultaneous cutting operations, which significantly increases production speed. This is especially beneficial in high-volume manufacturing environments where time is of the essence. By utilizing hot cutting technology, the machine ensures clean and precise edges, which helps to prevent fraying and enhances the overall quality of the finished garment. The hot cutting process not only cuts through the fabric but also seals the edges, providing a dual function that is both efficient and effective.

One of the standout characteristics of the Double Head Reverse Packaging Hot Cutting Machine is its ability to handle a variety of materials, including delicate fabrics and thicker textiles. This versatility makes it an indispensable asset for manufacturers who deal with diverse clothing lines and various garment types. Additionally, the machine is equipped with advanced controls that allow operators to easily adjust settings for different fabric types and cutting specifications, ensuring consistent results across all output.

Moreover, the reverse packaging feature of the machine reduces the need for manual intervention in packaging, which can often lead to errors and inconsistencies. By automating this process, manufacturers can achieve a higher level of precision in packaging, ensuring that garments are not only cut accurately but also presented in an appealing manner that reflects the brand's quality standards.

Sustainability is another crucial aspect in the garment industry today, and the Double Head Reverse Packaging Hot Cutting Machine contributes to this goal by minimizing fabric waste. The efficient cutting process, combined with smart layout planning, enables manufacturers to optimize material usage, which is a significant factor in reducing environmental impact.

In conclusion, the Double Head Reverse Packaging Hot Cutting Machine is more than just a tool; it is a vital component that enhances productivity, ensures quality, and supports sustainability in the garment manufacturing industry. Professionals in this field can greatly benefit from understanding the advantages this machine offers, making it a worthy consideration for any operation aiming to improve efficiency and output quality.

Previous Page:

Related Information

Revolutionizing Leather Production: The Innovative Applications of Back Buckle Technology

Revolutionizing Leather Production: The Innovative Applications of Back Buckle Technology Table of Contents 1. Introduction to Back Buckle Technology in Leather Production 2. Historical Context of Leather Production 3. What is Back Buckle Technology? 4. Innovative Applications of Back Buckle Technology 4.1 Automation and Efficiency 4.2 Enhancing Qu

Why an Automatic Cold Cutting Machine is Essential for Modern Textile Manufacturing

Why an Automatic Cold Cutting Machine is Essential for Modern Textile Manufacturing Introduction to Automatic Cold Cutting Machines In the rapidly evolving world of textile manufacturing, **efficiency and precision** are paramount. The automatic cold cutting machine stands out as a game-changer in the industry, enhancing productivity while ensuring the highest quality of fabric cutting. This advan