Why is a three-month maintenance cycle for production line equipment so crucial?

2025-04

Maintaining production line equipment every three months helps maintain stable equipment performance, prevent malfunctions, and improve production efficiency. It is an important measure to ensure smooth production.

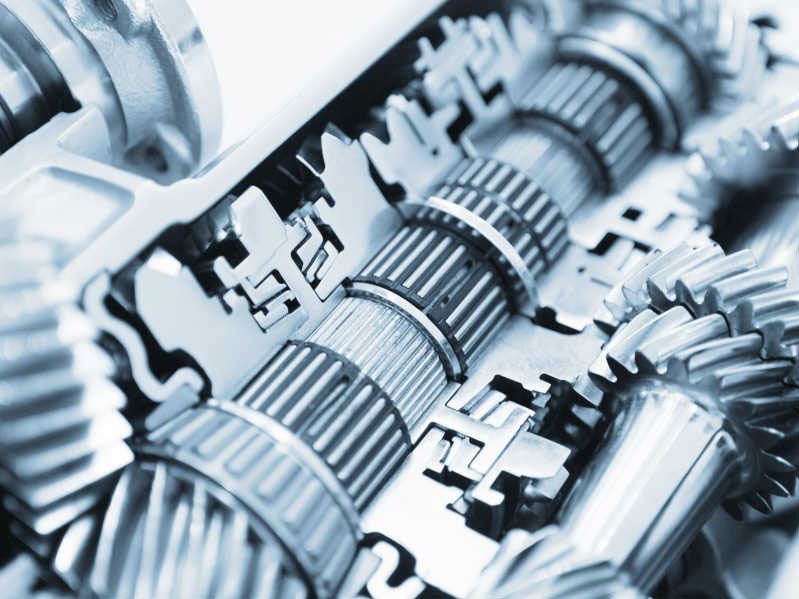

In industrial production, the maintenance and management of production line equipment is crucial. The normal operation of equipment not only relates to production efficiency and product quality but also directly affects the economic benefits and market competitiveness of enterprises. So, why is the maintenance cycle of production line equipment set to three months?

First, a three-month maintenance cycle helps maintain stable equipment performance. During continuous operation, various parts and components gradually wear and age, affecting equipment performance and accuracy. Through regular maintenance, worn parts can be identified and replaced in a timely manner, ensuring the equipment operates in optimal condition.

Second, regular maintenance helps prevent equipment malfunctions. During operation, various malfunctions may occur for various reasons. Through regular inspection and maintenance, potential safety hazards and signs of failure can be identified and addressed, preventing equipment malfunctions and ensuring stable production line operation.

In addition, a three-month maintenance cycle helps improve production efficiency. During maintenance, parts are inspected and maintained, and the equipment is optimized and adjusted for optimal operation. This improves production efficiency and reduces production downtime caused by equipment malfunctions, improving overall production line stability and efficiency.

In summary, setting the maintenance cycle of production line equipment to three months is a comprehensive consideration of factors such as maintaining equipment performance, preventing malfunctions, and improving production efficiency. Enterprises should attach great importance to regular equipment maintenance to ensure stable production line operation and sustainable development.

Related Information

Choosing the Right Supplier for Your Automatic Cold Cutting Machine Needs: A Comprehensive Guide

Choosing the Right Supplier for Your Automatic Cold Cutting Machine Needs Table of Contents Understanding Automatic Cold Cutting Machines The Importance of Selecting the Right Supplier Key Features of a Quality Supplier Evaluating Supplier Reputation and Experience Assessing Technical Expertise and Support Considering Cost-Effectiveness and Value Ensuring Compliance an

Understanding Fully Automatic Cutting and Bundling Machines in the Garment Manufacturing Industry

In the fast-paced apparel manufacturing industry, efficiency and precision are paramount. Fully automatic cutting and bundling machines have emerged as vital tools that streamline production processes, ensuring that manufacturers can meet high demands while maintaining quality. These machines automate the cutting and bundling of fabric materials, eliminating manual labor and minimizing human error