Product Series

Contact Information

DEMAO UNDERWEAR BRUSHING MACHINE

- Commodity name: DEMAO UNDERWEAR BRUSHING MACHINE

Keywords:

Automation Equipment

- Product Description

-

Product Introduction

The Demou automatic glue applicator uses a doctor blade device to evenly apply glue to the surface of the fabric according to preset parameters. Factors such as the pressure between the doctor blade and the fabric and the moving speed of the doctor blade determine the amount and uniformity of glue application. A screen printing machine utilizes the principle that ink passes through the mesh openings in the screen printing plate in the graphic areas, while it does not pass through the mesh openings in the non-graphic areas. Glue is poured into one end of the screen printing plate, and pressure is applied with a squeegee and moved to the other end, squeezing the glue from the mesh openings in the graphic areas onto the underwear fabric. It features a high degree of automation, automatically completing processes such as glue application and removal, reducing manual intervention, improving production efficiency, and precisely controlling the amount, position, and shape of glue application to ensure even glue application to the fabric and bonding quality. Operation is simple. It is equipped with an intuitive operating interface, easy for workers to master, reducing the technical requirements for operators. Parameters can be adjusted to adapt to underwear fabrics of different materials and thicknesses, as well as different types of glue.

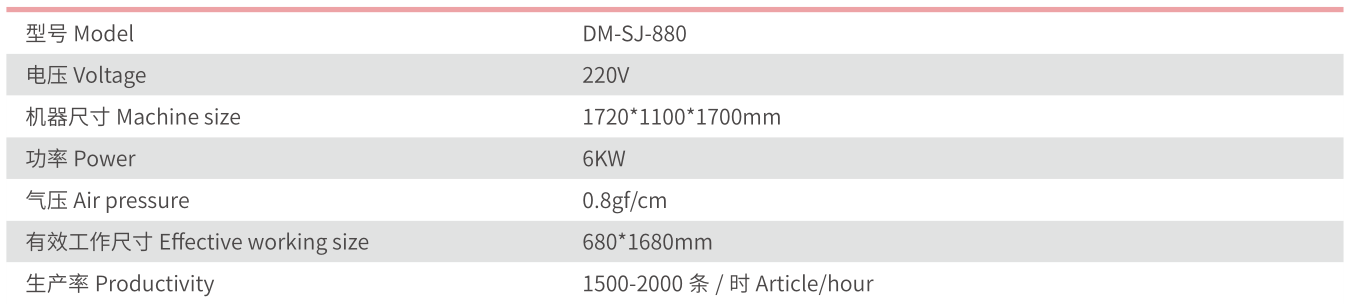

Technical Parameters

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!