Product Series

Contact Information

DEMAO ADHESIVE BRUSHING MACHINE

- Commodity name: DEMAO ADHESIVE BRUSHING MACHINE

Keywords:

Automation Equipment

- Product Description

-

Product Introduction

The Demao bonding brush glue integrated machine uses a scraper and a workbench suction bonding device to evenly apply glue to the surface of the fabric according to the set parameters. The pressure between the scraper and the fabric, as well as the speed of the scraper's movement, determine the amount and uniformity of adhesive application. For screen printing machines, adhesive is applied through the mesh holes of the graphic and textual parts of the screen printing plate. Pour glue into one end of the screen printing plate, apply pressure to the glue area with a scraper and move it towards the other end. The glue is squeezed from the mesh of the graphic and text parts by the scraper onto the underwear fabric, with a high degree of automation to automatically complete the gluing, gluing, and other processes, reducing work intervention. Combined with a dual worktable for air suction to achieve the bonding effect, the pressure range can be adjusted, and it can handle multi-layer thick fabrics from gentle pressing of thin fabrics to high curvature pressing, meeting various underwear production requirements. Through advanced pressure control system and mechanical structure, the pressure is evenly distributed on the pressing surface during the pressing process, ensuring consistent bonding effect of all parts of the underwear, avoiding local overpressure or weak pressing, and ensuring a smooth surface of the fabric during the bonding process. No wrinkles, bubbles or other defects, improving the appearance quality of underwear, The operation interface is simple and intuitive. Compared with traditional split machines, it greatly improves production efficiency and reduces labor costs. Staff can operate proficiently after simple training.

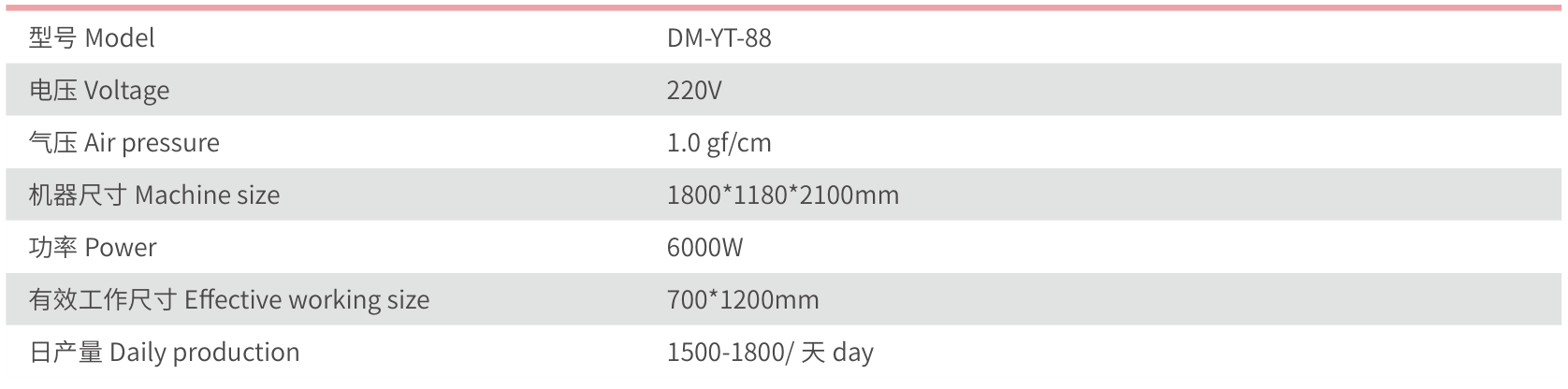

Technical Specifications

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!