Product Series

Contact Information

DEMAO BACK BUCKLE DOUBLE PRESSURE BONDING MACHINE

- Commodity name: DEMAO BACK BUCKLE DOUBLE PRESSURE BONDING MACHINE

Keywords:

Automation Equipment

china Back Buckle Double Pressure Bonding Machine

- Product Description

-

Product Introduction

Back button double pressure bonding machine: integrating pre ironing, hot pressing, and cold pressing into one.

1. Pre ironing and shaping calibration: Through the synergistic effect of preheating and pressure, the back buckle is preliminarily fixed in shape and calibrated in position to ensure that it maintains precise shape and position during subsequent processing. Before formal stitching or pasting, preheat the back buckle and the area in contact with the fabric to achieve preliminary shaping of the material, laying the foundation for subsequent hot pressing processes.

2. Hot pressing bonding process: With the help of high-temperature hot pressing technology, the internal adhesive layer of the fabric is fully melted, achieving a tight bonding between the back buckle and the fabric from the surface of the fabric, ensuring a firm and reliable bonding effect.

3. Cold pressing and shaping reinforcement: For the back buckle and material after hot pressing, cold pressing and shaping operations are performed to further regulate the shape of the back buckle, strengthen the stability of the connection between the back buckle and the material, and effectively avoid problems such as back buckle loosening and deformation during use.

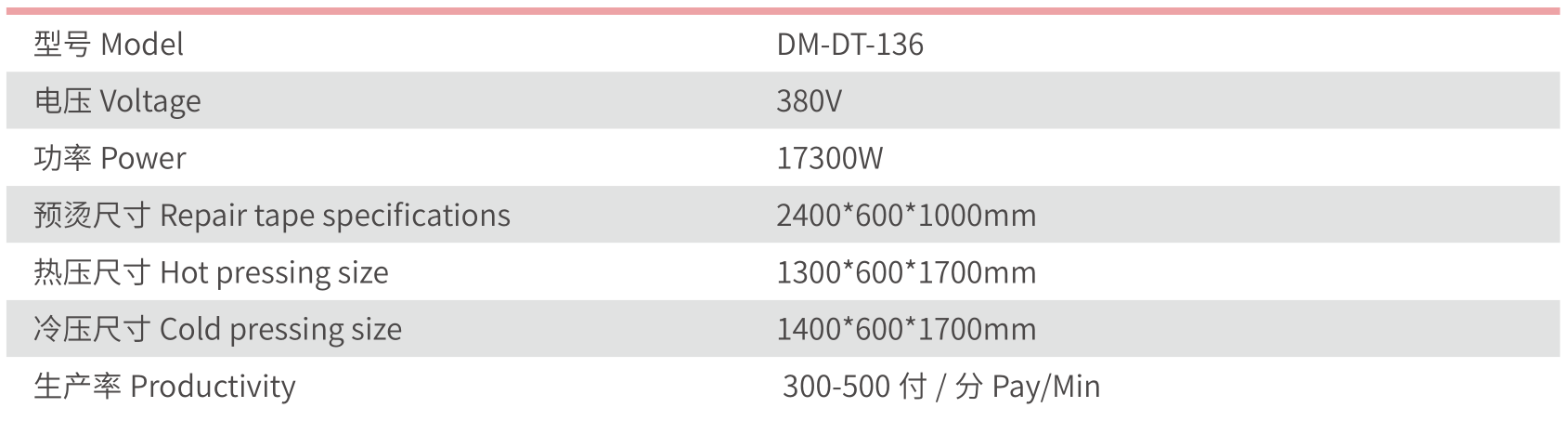

Equipped with advanced automation control system, integrating automatic loading, hot pressing, cold pressing, and unloading processes, significantly improving production efficiency while ensuring product quality stability, achieving efficient and precise industrial production.Technical Parameters

The quality Back Buckle Double Pressure Bonding Machine is an innovative and highly efficient piece of equipment.

This machine is designed with precision engineering. It features a back buckle mechanism, which provides enhanced stability during the bonding process. The double - pressure system is its standout feature. It applies two levels of pressure precisely, ensuring a strong and reliable bond. This is especially crucial for applications where the integrity of the bond is of utmost importance, such as in electronics or high - end manufacturing.

The machine is made from high - quality materials, which not only contribute to its durability but also its performance. It can handle a variety of materials to be bonded, from thin and delicate components to more robust ones.

In terms of operation, it is user - friendly. The controls are intuitive, allowing operators to easily set the desired pressure levels, bonding time, and other parameters. This reduces the learning curve and increases productivity in the production line.

It also has excellent safety features. Protective mechanisms are in place to prevent any accidents during operation, safeguarding the operators and the surrounding environment.

The quality Back Buckle Double Pressure Bonding Machine is a reliable choice for industries that require high - quality bonding. Its advanced features, ease of use, and safety measures make it an ideal investment for enhancing production capabilities and product quality.

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!